The drink platform and actuator are both essential structural pieces in SirMixABot’s design. Plasma cutting steel is the logical solution to both reduce cost and produce reliable, durable parts for our robotic bartender. Although laser cutting is used for the enclosure, it is not viable for thicker metals and rigid components. As an added bonus, the visual combination of steel, wood, 3D printed parts is astonishing. Check out the finished product below as well as some of our other component highlights to see for yourself.

Plasma Cutting the Parts

The material used is a 1/8″ mild steel. For the current production model we used a Miller plasma cutter running at around 28 amps. At a cut speed of roughly 32 inches per minute the cuts penetrate fully without producing any waves. The video above highlights the cutting process for the upper drink actuator. The other CNC cut part is the drink platform, an essential piece in our automated bar. This is cut using the same sheet of steel, and can even be done in the same run. Combined plasma cutting time is about ten minutes using these settings. Take a look at the final product below.

The Final Product

The two pieces are removed easily with the tap of a hammer. Once cooled, there are typically a few rough edges or excess steel to be removed. Pliers and a file work well to remove these extra parts. The circular holes can also be cleaned using a drill. Alternatively, the face of each plate can be sanded or ground down to smooth out the edges. These pieces serve as the stable foundation for mounting 90% of SirMixABot’s tech. Sensors, rails, drive rods and more will be mounted to these platforms. It’s important to have precision and strength for each of them, and plasma cutting was the clear solution for our product.

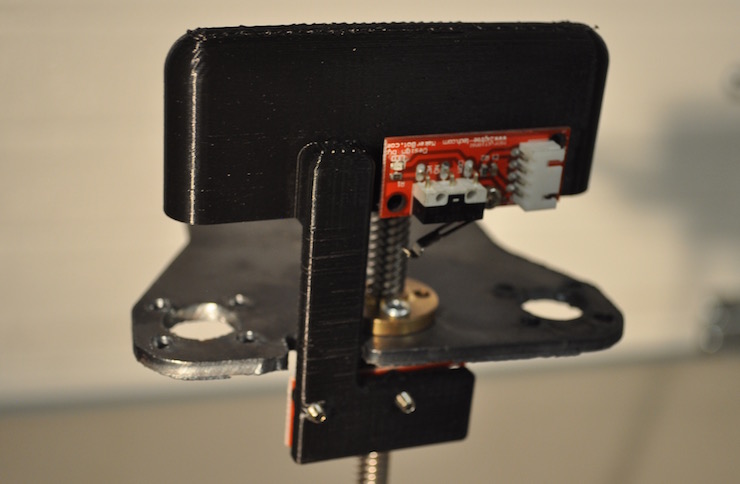

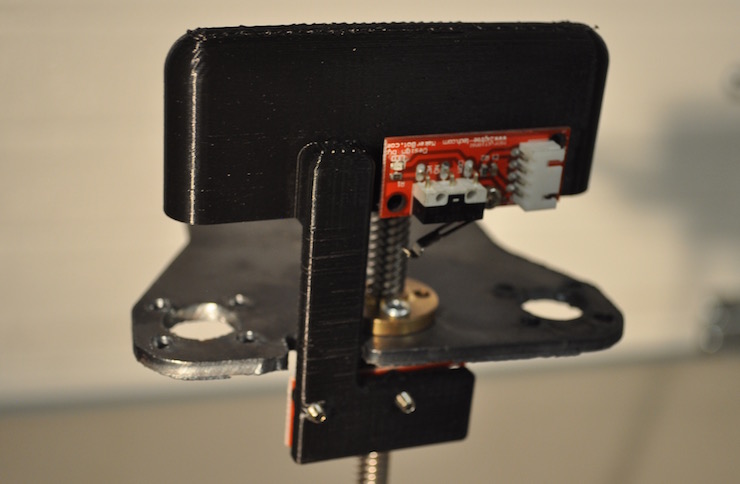

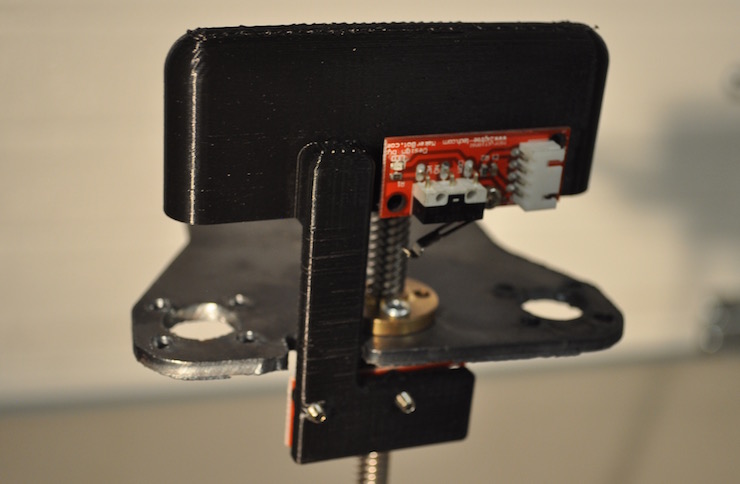

The Installed Application

As mentioned, the drink platform and upper drink actuator are both critical structural pieces. The two are connected by the linear drive rod, which is fixed to the stepper motor on the drink platform. The upper actuator is attached to the drive rod by the brass drive nut, allowing it to move vertically. The 3D printed parts allow for the precise fit of limit switches and the infrared sensor, while the steel plates don’t need to be as precise. SirMixABot organizes your liquor cabinet into a ready to pour automated bartender. Its open source coding and cocktail app let you control what you want to drink, and how you want to drink it. Check out our comparison test to see how SirMixABot stands up against the competition, and decide for yourself who you want making your next drink!